H05VV-FA05VV-F - PVC Sheathed Cable

H05VV / FA05VV-F | PVC Sheathed Cable

Product Descriptions

Suitable for use in household electrical appliance connections subjected to moderate mechanical stress in dry and humid environments. It works safely in white goods such as washing machines, refrigerators and heating appliances (if there is no risk of direct contact with hot surfaces).

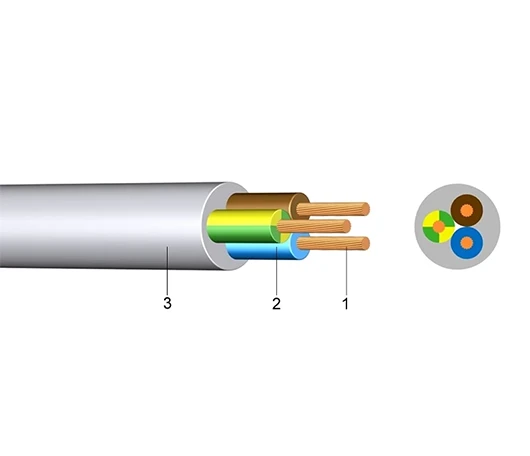

Structure

- Conductor Fine stranded bare copper (Class 5)

- Insulation Polyvinylchloride (PVC)

- Outer Sheath: Polyvinylchloride (PVC)

Standards

- DIN VDE 0281-5

- HD 21.5 S3 + A1 + A2

- DIN EN 60228 Class 5 (conductor structure)

- HD 308 S2 (vessel identification)

- PRAISE/PREFORM E 8241 (HD 21)

Technical Data

Feature Value

- Rated Voltage U₀/U [V] 300 / 500

- Test Voltage [V AC] 2000

- Temperature Range (moving) -5 °C ... +70 °C

- Short Circuit Operating Temperature [°C] 150

- Short Circuit Time (max.) [s] 5

- Bend Radius 5 × cable outer diameter

- Flame Retardancy Standard EN 60332-1-2

| Number of Cores and Cross Section (mm²) | Colors | Copper Quantity (kg/km) | Conductor Construction (pcs × mm) | Outer Diameter (mm) | Weight (kg/km) |

|---|---|---|---|---|---|

| 2 × 1 | lgr | 19,20 | 30 × 0,21 | 7,5 | 67 |

| 2 × 1 | bk/wt | 19,20 | 30 × 0,21 | 7,5 | 67 |

| 2 × 1,5 | lgr | 28,80 | 30 × 0,26 | 8,6 | 89 |

| 2 × 1,5 | bk/wt | 28,80 | 30 × 0,26 | 8,6 | 89 |

| 2 × 2,5 | lgr | 48,00 | 50 × 0,26 | 10,6 | 134 |

| 2 × 2,5 | bk | 48,00 | 50 × 0,26 | 10,6 | 134 |

| 3 G 0,75 | lgr | 21,60 | 24 × 0,21 | 7,6 | 64 |

| 3 G 0,75 | wt | 21,60 | 24 × 0,21 | 7,6 | 64 |

| 3 G 1 | lgr | 28,80 | 30 × 0,21 | 8,0 | 80 |

| 3 G 1 | wt/bk/br | 28,80 | 30 × 0,21 | 8,0 | 80 |

| 3 G 1,5 | lgr | 43,20 | 30 × 0,26 | 9,4 | 120 |

| 3 G 1,5 | bk/wt/br/or | 43,20 | 30 × 0,26 | 9,4 | 120 |

| 3 G 2,5 | lgr | 72,00 | 50 × 0,26 | 11,4 | 175 |

| 3 G 2,5 | bl/ws | 72,00 | 50 × 0,26 | 11,4 | 175 |

| 4 G 1 | lgr | 38,40 | 30 × 0,21 | 9,0 | 94 |

| 4 G 1 | bk/wt | 38,40 | 30 × 0,21 | 9,0 | 94 |

| 4 G 1,5 | lgr | 57,60 | 30 × 0,26 | 10,5 | 130 |

| 4 G 1,5 | bk/wt | 57,60 | 30 × 0,26 | 10,5 | 130 |

| 4 G 2,5 | lgr | 96,00 | 50 × 0,26 | 12,5 | 200 |

| 4 G 2,5 | bk/wt | 96,00 | 50 × 0,26 | 12,5 | 200 |

| 4 G 4 | lgr | 153,60 | 56 × 0,31 | 14,3 | 280 |

| 5 G 0,75 | lgr | 36,00 | 24 × 0,21 | 9,3 | 100 |

| 5 G 0,75 | bk/wt | 36,00 | 24 × 0,21 | 9,3 | 100 |

| 5 G 1 | lgr | 48,00 | 30 × 0,21 | 9,8 | 120 |

| 5 G 1 | wt/bk | 48,00 | 30 × 0,21 | 9,8 | 120 |

| 5 G 1,5 | lgr | 72,00 | 30 × 0,26 | 11,6 | 170 |

| 5 G 1,5 | bk/wt/or | 72,00 | 30 × 0,26 | 11,6 | 170 |

| 5 G 2,5 | lgr | 120,00 | 50 × 0,26 | 13,9 | 250 |

| 5 G 2,5 | bk/wt/or | 120,00 | 50 × 0,26 | 13,9 | 250 |

| 5 G 4 | lgr | 192,00 | 56 × 0,31 | 16,1 | 350 |

| 5 G 4 | wt | 192,00 | 56 × 0,31 | 16,1 | 350 |

| 5 G 6 | lgr | 288,00 | 84 × 0,31 | 16,5 | 480 |

| 5 G 6 | wt | 288,00 | 84 × 0,31 | 16,5 | 480 |

| 7 G 1 | lgr | 67,20 | 30 × 0,21 | 9,0 | 150 |

| 7 G 1,5 | lgr | 100,80 | 30 × 0,26 | 10,4 | 196 |

| 7 G 1,5 | bk | 100,80 | 30 × 0,26 | 10,4 | 196 |

| 7 G 2,5 | lgr | 168,00 | 50 × 0,26 | 13,1 | 315 |

| 10 G 1,5 | lgr | 144,00 | 30 × 0,26 | 14,0 | 305 |