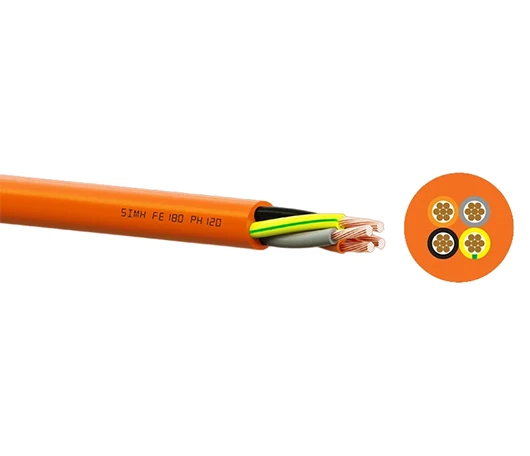

SIMH FE180 PH120 - High Temperature and Circuit Integrity Silicone Insulated Cable

SIMH FE180 PH120 | High Temperature and Circuit Integrity Silicone Insulated Cable

Areas of Use

- Connection points exposed to extreme temperature variations

- Iron and steel production industry

- Aviation industry

- Shipbuilding industry

- Lighting fixtures

- Ceramic, glass and cement factories

Cable Structure

- Conductor Stranded annealed copper wires (HD 383 Class 5)

- Insulation Silicone compound (HD 22.1 S4 I El2)

- Vessel Identification: Color-coded or numbered printing according to DIN VDE 0293-308

- Operating Temperature: -60 °C ... +200 °C

- Outer Case: Silicone compound (HD 22.1 S4 I EM9), orange

Applied Tests

- Structural Dimension Tests: HD 22.1-2

- Mechanical Tests: EN 60811-1-1, -1-2, -2-1

- Electrical Tests HD 22.2

- Low Temperature Tests: EN 60811-1-4

Fire Performance Tests

- Flame Retardancy: IEC 60332-1-2 - VDE 0482-332-1-2 - EN 60332-1-2

- Smoke Density: IEC 61034-2 - VDE 0482-1034-2 - EN 61034-2

- Corrosive Gas Emission: IEC 60754-2 - VDE 0482-754-2 - EN 60754-2

Electrical and Circuit Integrity Properties

- Isolation Integrity: 180 minutes (FE180)

- Circuit Integrity 120 minutes (PH120)

| Number of Cores × Cross Section (mm²) | Outside Diameter Approx. (mm) | Copper Factor (kg/km) | Cable Weight (kg/km) |

|---|---|---|---|

| 2 × 0,75 | 6,2 | 14,4 | 54,4 |

| 3 × 0,75 | 6,6 | 21,6 | 66,0 |

| 4 × 0,75 | 7,6 | 29,0 | 86,2 |

| 2 × 1,00 | 6,6 | 19,2 | 63,4 |

| 3 × 1,00 | 7,4 | 29,0 | 84,2 |

| 4 × 1,00 | 8,0 | 38,4 | 101,2 |

| 2 × 1,50 | 7,4 | 29,0 | 82,7 |

| 3 × 1,50 | 7,9 | 43,0 | 101,8 |

| 4 × 1,50 | 8,5 | 58,0 | 123,5 |

| 2 × 2,50 | 9,1 | 48,0 | 127,1 |

| 3 × 2,50 | 9,7 | 72,0 | 157,0 |

| 4 × 2,50 | 10,5 | 96,0 | 191,0 |

| 2 × 4,00 | 10,6 | 77,0 | 181,3 |

| 3 × 4,00 | 11,3 | 115,0 | 227,5 |

| 4 × 4,00 | 12,6 | 154,0 | 296,2 |