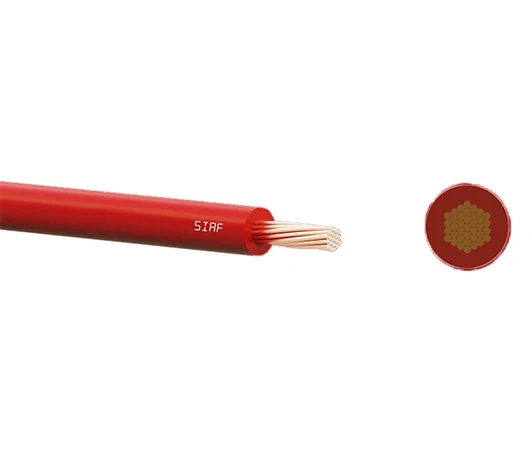

SIAF - High Temperature Resistant Silicone Insulated Cable

SIAF | High Temperature Resistant Silicone Insulated Cable

Areas of Use

Suitable for use in connection points where extreme temperature changes are intense. It is preferred in harsh environments such as iron and steel production facilities, aviation and shipbuilding industry, lighting fixtures, ceramic, glass and cement factories.

Cable Structure

- Conductor Stranded annealed copper wires (HD 383 Class 5)

- Insulation Silicone compound (HD 22.1 S4 I El2)

- Color Various color options (DIN 47100 coded)

- Operating Temperature: - 60 °C ... + 200 °C

- Operating Voltage: 450 / 750 V

Applied Tests

- Structural Dimension Tests: HD 22.1-2

- Mechanical Resistance: EN 60811-1-1, EN 60811-1-2, EN 60811-2-1

- Electrical Tests HD 22.2

- Low Temperature Tests: EN 60811-1-4

Fire Performance Tests

Flame Retardancy

- IEC 60332-1-2

- VDE 0482-332-1-2

- EN 60332-1-2

Smoke Density:

- IEC 61034-2

- VDE 0482-1034-2

- EN 61034-2

Corrosive Gas Emission:

- IEC 60754-2

- VDE 0482-754-2

- EN 60754-2

| Number of Cores × Cross Section (mm²) | Outside Diameter Approx. (mm) | Copper Factor (kg/km) | Cable Weight (kg/km) |

|---|---|---|---|

| 1 × 0,25 | 1,7 | 2,4 | 5,0 |

| 1 × 0,50 | 2,1 | 4,8 | 9,0 |

| 1 × 0,75 | 2,3 | 7,2 | 12,0 |

| 1 × 1,00 | 2,5 | 9,6 | 15,0 |

| 1 × 1,50 | 2,7 | 14,4 | 19,0 |

| 1 × 2,50 | 3,4 | 24,0 | 30,0 |

| 1 × 4,00 | 4,1 | 38,4 | 45,0 |

| 1 × 6,00 | 4,8 | 57,6 | 65,0 |

| 1 × 10,0 | 6,1 | 96,0 | 111,0 |

| 1 × 16,0 | 7,7 | 153,6 | 171,0 |

| 1 × 25,0 | 9,6 | 240,0 | 268,0 |

| 1 × 35,0 | 10,6 | 336,0 | 356,0 |

| 1 × 50,0 | 12,4 | 480,0 | 509,0 |

| 1 × 70,0 | 14,6 | 672,0 | 720,0 |

| 1 × 95,0 | 16,6 | 912,0 | 994,0 |

| 1 × 120,0 | 18,9 | 1152,0 | 1200,0 |

| 1 × 150,0 | 20,5 | 1440,0 | 1510,0 |

| 1 × 185,0 | 24,5 | 1176,0 | 1880,0 |

| 1 × 240,0 | 25,9 | 2304,0 | 2550,0 |